Did you know that the water base house paint in your garage can create some pretty spectacular glazes when fluxed in an atmospheric firing such as the Kazegama, salt and soda? Many common products we use are loaded with ceramic materials from talc to silica to clays. There is a ton of titanium dioxide in many white paints and primers which can create a lot of crystals as shown on these test tiles. So try it out. Make sure there’s going to be decent contact with fluxes during the firing. These tiles were up front in the firebox of the Kazegama where they came into contact with wood ash.

Glazes, Glazes and more Glazes….

Yo Peoples. It’s been a while since I posted anything. Hope you are all well.

I have gone through the “old site” glaze pages and organized glaze and clay formulas into PDFs.

These are glazes I have collected over my lifetime, but I haven’t had a lifetime to spend documenting them through the glaze mixing process and posting them. So some are great, and some are a hodge podge.

They can be found on the “Glazes” link.

An Oxidized Bisque Firing

Bisque Firing – Pottery Making Illustrated

Originally published in Pottery Making Illustrated, July/August 2018. http://potterymaking.org. Copyright, The American Ceramic Society. Reprinted with permission.

Kazegama Workshop 05-05-2018

Kazegama Workshop 3-17-2018

Komakigama

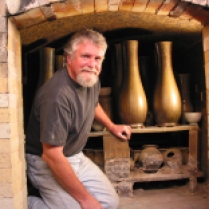

When I was 17 years old, way back in 1974, my first introduction to ceramics were Shigaraki jars that were wood-fired and made with clays ladened with decomposed granite. Read more here..

The Deep Stillness of a Raku Tea Bowl | Nippon.com

Black Raku chawan, or tea bowls, are currently gaining global attention. The founder of the Raku family of potters created this implement at the request of Sen no Rikyū, who elevated the Japanese tea ceremony to entirely new levels of refinement. What is the allure of these tea bowls that crosses national borders? We asked Raku Kichizaemon XV, the current head of the Raku family, about their appeal.

Black Raku chawan, or tea bowls, are currently gaining global attention. The founder of the Raku family of potters created this implement at the request of Sen no Rikyū, who elevated the Japanese tea ceremony to entirely new levels of refinement. What is the allure of these tea bowls that crosses national borders? We asked Raku Kichizaemon XV, the current head of the Raku family, about their appeal.

Kazegama Workshop – Oct. 15, 2016

Kaz Ota introducing lemon wood ash from an Akagama wood firing and Jamie Boran blowing out the burners and ports at Aardvark Clay & Supplies. Continue reading

Micro Mondays: Crystals of Color | NCECA Blog

Have you ever wondered what causes “flashing” colors on bare clay in atmospheric (e.g. wood, salt or soda) firings?

Have you ever wondered what causes “flashing” colors on bare clay in atmospheric (e.g. wood, salt or soda) firings?